The Agasti Make Gauge Pole Cover for Floating Roof Oil Storage Tanks is an innovative solution to emission reductions in Floating Roof Tanks. To control the emissions for IFR/ EFR is its main purpose.

GPC is designed to inhibit hydrocarbons from escaping through slots in Slotted Gauge Poles. The owners will save the loss by reducing product emissions while meeting environmental regulation, and protect our environment from atmospheric contamination.

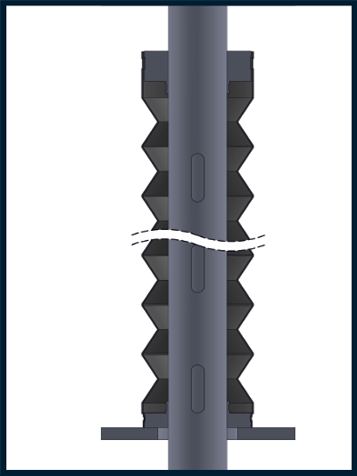

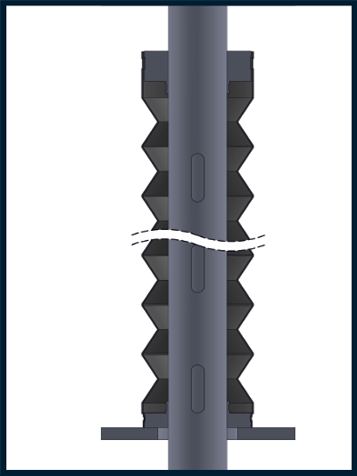

GPC is manufactured using aromatic resistance seal material to form a casing around the Slotted Gauge Pole. The optional Transition Box provides a seal at the negotiator area on the top of the floating roof.

The Agasti Make Gauge Pole Cover is designed to seal the Slotted Holes around the gauge pole, which is an essential part of floating roof oil storage tanks used for measuring the tank’s contents. By effectively sealing this gap, the gauge pole cover minimizes vapor losses and enhances the environmental safety of the storage system.