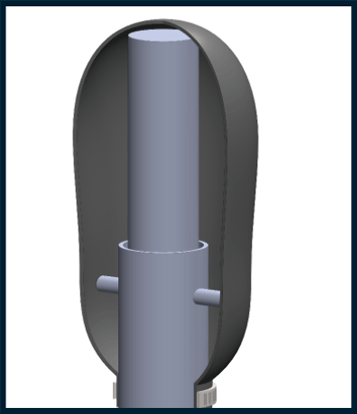

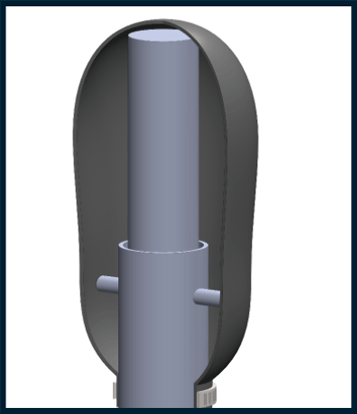

The Agasti Make Landing Leg Sock for Floating Roof Oil Storage Tanks is a specialized accessory designed to enhance vapour control and prevent product loss in floating roof tanks. Here’s an in-depth look at this product:

The Agasti Make Landing Leg Sock is designed to seal the gaps around the landing legs of floating roof tanks. Landing legs are used to support the floating roof when the tank is emptied or during maintenance. By sealing these gaps, the landing leg sock minimizes vapour losses and enhances the safety and environmental performance of the storage system.

Enhanced Vapor Control: Significantly reduces the release of volatile organic compounds (VOCs), contributing to a reduction in air pollution.

Improved Safety: By maintaining a tight seal around the gauge pole, it reduces the risk of flammable vapour escape, enhancing the safety of the storage facility.

Cost Savings: Minimizes product loss through evaporation, leading to cost savings over the operational life of the tank.

Regulatory Compliance: Helps storage facilities comply with environmental regulations, avoiding potential fines and ensuring legal operation.

Crude Oil Storage Tanks

Refind Petroleum Product Tanks

Chemical Storage Tanks

Any Floating Roof Tank Requiring Liquid Level Vapor Control

Material Composition: High-quality, corrosion-resistant materials such as stainless steel, aluminum, or robust polymers.

Design: Customizable to fit various roof leg sizes and configurations, with options for different sealing mechanisms.

Temperature Range: Designed to perform effectively within the temperature ranges typically encountered in oil storage tanks.

Compatibility: Suitable for use with a wide range of petroleum products and chemicals.