The Agasti Make Submerged Shunt for Floating Roof Oil Storage Tanks is an essential safety component designed to prevent static electricity buildup, thereby enhancing the safety of floating roof tanks. Here's a detailed overview of this product:

The Agasti Make Submerged Shunt is designed to provide a continuous electrical path between the floating roof and the tank shell, which helps in preventing the accumulation of static electricity. This is crucial for reducing the risk of sparking and potential ignition of flammable vapours within the storage tank.

Enhanced Safety: Reduces the risk of sparks and potential ignition sources by providing continuous grounding, thereby enhancing the overall safety of the storage facility.

Reliable Performance: Ensures consistent electrical continuity even under varying operational conditions, providing peace of mind for operators.

Durable and Long-Lasting: Constructed from materials that resist corrosion and degradation, ensuring a long service life.

Compliance: Helps storage facilities comply with safety regulations and industry standards, avoiding potential fines and ensuring safe operation.

Crude Oil Storage Tanks

Refind Petroleum Product Tanks

Chemical Storage Tanks

Any Floating Roof Tank Requiring Liquid Level Vapor Control

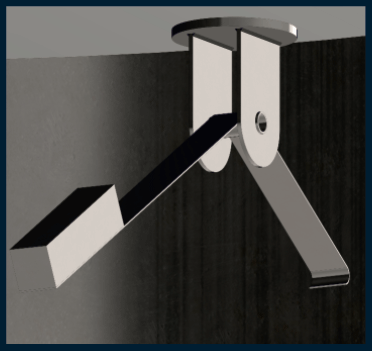

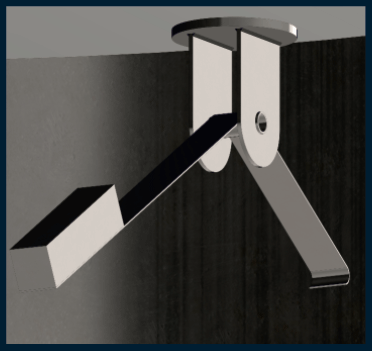

Material Composition: High-quality, corrosion-resistant materials such as stainless steel or other conductive alloys.

Design: Optimized for submerged operation, ensuring effective grounding regardless of the tank's fill level.

Temperature Range: Designed to operate efficiently within the temperature ranges typically encountered in oil storage tanks.

Compatibility: Suitable for use with a wide range of petroleum products and chemicals.